Under moderate to severe humidity conditions, the low density epoxy coating of radial film capacitors does not provide reliable humidity protection, even if other potting compounds are used.

In ADDITION, THERE IS no CLEAR PICTURE TO SHOW THE cracks THAT OCCUR at the pin outlet POINTS during the automatic installation of the insertion elements, which further affect their resistance to humidity.

|

|

|

| Box class | Assault glues |

|

Two casting steps ensure protection against high humidity.

|

There are more pores in the surface coating.

|

Uniform size

Radial boxed film capacitors provide uniform size, optimized space and consistency of front and rear purchased materials.

In addition, it allows for greater flexibility when the auto-insert component is larger.

|

Box class

All dimensions are clearly defined.

|

|

|

Assault glues

Only pin spacing is defined.

|

|

Precise setting of PC board

Because radial dip film capacitors rely on their solder joints rather than the entire support of the box body, any vibrations the container may encounter will be transmitted to the pins.

This is particularly noteworthy in AC applications where self-generated electrical and mechanical vibration accelerates solder joint aging.

|

Box class

The capacitor depends on the box support.

|

|

|

Assault glues

Capacitors depend on solder joints.

|

|

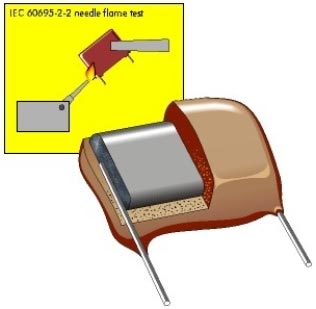

Flame retardant

The extremely thin coating, coupled with the presence of pores in the coating, raises questions about the passive and active combustibility of the dip film package, especially in the absence of any compound potting.

On the other HAND, THE boXED construction and resin filled technology provides high grade flame retardant properties, especially for capacitors in AC applications such as power line filters and a range of lighting applications. v

|

Box class

Consistent package size.

Complies with UL 94V-0 flame retardant rating.

|

|

Assault glues Epoxies may ignite by active or passive ignition. The thinner coating allows the flame to enter the winding element in a short time. Coating bubbles tend to irritate the flame. Tar is flammable when used on fire.

|

Radial frame film capacitors need to disappear for potting when used, as frame capacitors provide adequate humidity and flammability protection, as well as mechanical integrity from shocks and vibrations generated internally or externally. Radial boxed film capacitors, complete seal characteristics, provide boxed capacitors with adequate humidity and flammability protection.

And casting integrity, more effective in the face of external or internal generated shocks and vibrations.

In many cases, a qualified capacitor, often need to be applied under harsh environment and working conditions, can not be replaced or maintenance of the continuous work for many years, whether the components meet the highest standards of packaging technology, even if it becomes the most important key.

Without such standards, it is impossible to guarantee the safe and reliable operation of the product. The boxed film capacitor process is specifically designed to meet this challenge, similar to radial SMD products.