This information describes the plastic film dielectric material used to fix capacitors, also known as film capacitors or FK capacitors.

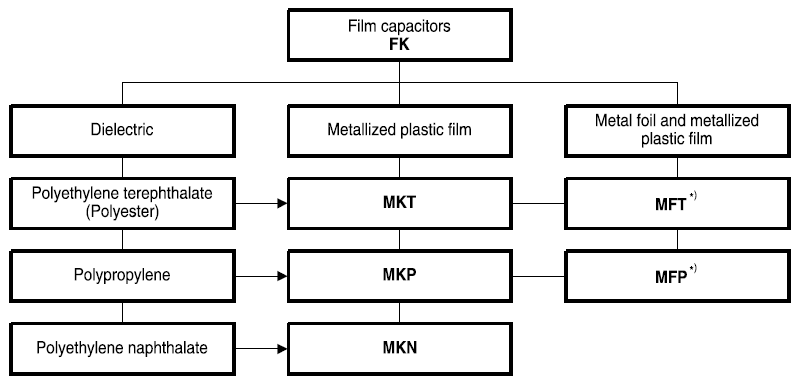

Classification of film capacitors

1. Classification of dielectric

Film capacitors have different characteristics and applications depending on the material classification of the medium.

According to the abbreviation of the structure type, in DIN41379, the medium and the basic technology and applications are described.

The last letter of an abbreviation, indicating the type of medium:

T = Polyester (PET)

P = Polypropylene (PP)

N = naphthalate (PEN)

The prefix is M (Metallization), which refers to the metallized structure film capacitor.

FIG. 1 Classification of DIN41379 film capacitors

*) MFP and MFT are a combination of metal foil and metallized plastic film. They do not belong to DIN41379

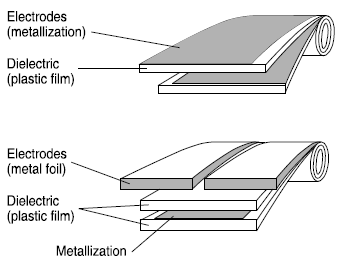

2. Classification of thin film and foil deployment

To better understand the differences in the internal structure of a capacitor, Figure 2 shows two typical stacking combinations of film and foil.

FIG. 2 A typical example of a laminated film and foil combination

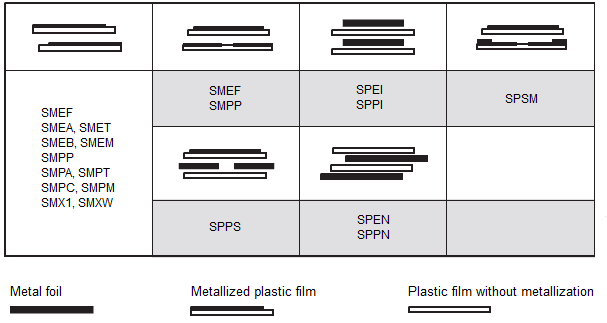

Figure 3 shows the relationship between various films and metal foils and types of capacitors

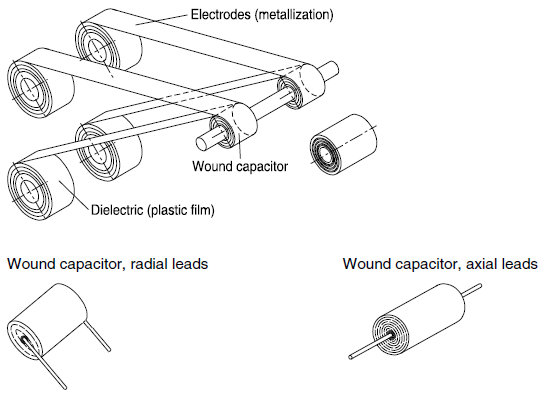

3. Classification of structure

Weedy makes FK capacitors by winding them.

The winding technique:

In a typical production process, capacitors are made of individual cylindrical reels, rolled metallized film and foil, and covered with an insulating shell or coating.

Figure 4. General production winding technique

In THE MKT, MKP AND MFP SERIES, WE PRODUCE A RANGE OF TYPES THAT ARE WOUND PRESSED AND COVERED WITH AN INSULATING COATING, OR PACKED IN PLASTIC ENCLOSURES FOR SPACE SAVING, AND CYLINDRICAL WINDING CAPACITORS. The flat winding capacitor, which is not pressed again, is designed to be installed in a cylindrical housing with more intentional features.